MAINTENANCE FOR SCREENS & IMPELLERS

Quadro recommends replacing the screen and/or impeller at the first sign of damage or wear indicated by one or more of the following criteria:

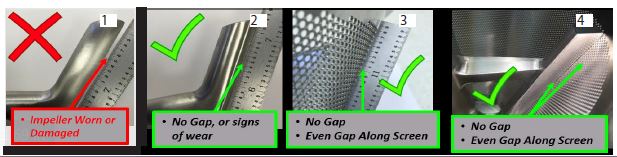

1) Visible gap between impeller and screen as shown below:

2) Particle Size Distribution shifts toward more fines

3) Increase in Run Time by 10-15% or more – Indicates potentially worn tooling and/or material changes

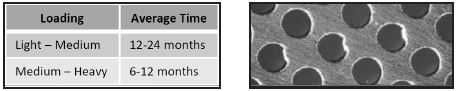

4) Screen Blinding – Holes in the screen are filling with product (also related to #6)

5) Increase in Temperature – related to 2) and 3) above, the temperature will increase

6) Hole Shape or Size Deformation, Screen Damage as shown below:

7) Runtime Exceeds

SCREEN & IMPELLER INSPECTION

Method #1 – as shown in pic. 4:

1) Remove the Screen & Impeller from the equipment

2) Place the Impeller in the Screen, making sure to center the impeller as best as possible in the screen

3) Observe the area where the impeller arm rests against the screen, there should be no gap. On grater screens some gap will be visible due to rasp profile, however top of rasp should touch the impeller arm evenly. Note on Underdriven tooling the screen must be raised during inspection to allow for bottom of impeller to protrude through screen bottom opening

Method #2 – as shown in pic. 1-3:

1) Remove the Screen & Impeller from the equipment

2) To inspect the Impeller, place a straight edge along the Impeller arm, the arm should be straight

3) To inspect the Screen, place a straight edge along the outside of screen