SafeFlex isolators enable contained processes quickly, easily, and inexpensively

April 22, 2021

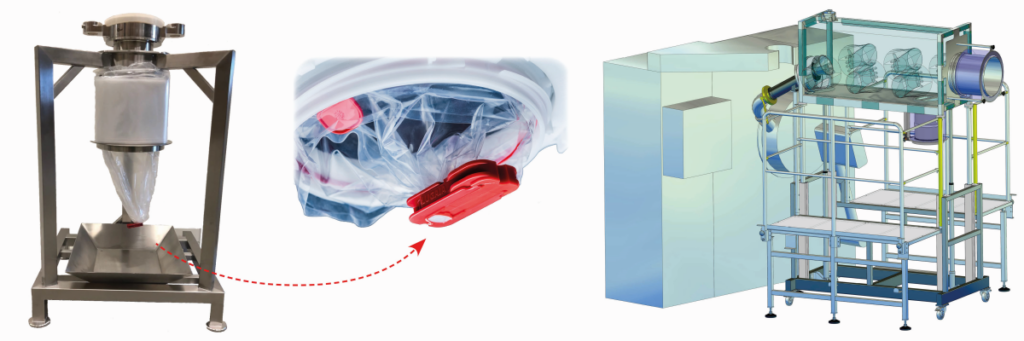

THURNE in cooperation with LUGAIA is proud to present containment solutions for safe powder handling using Flexible Isolators.

The feed of raw materials to the tablet press can be done in a closed manner using the SafeFlex isolator or SafePortBag system.

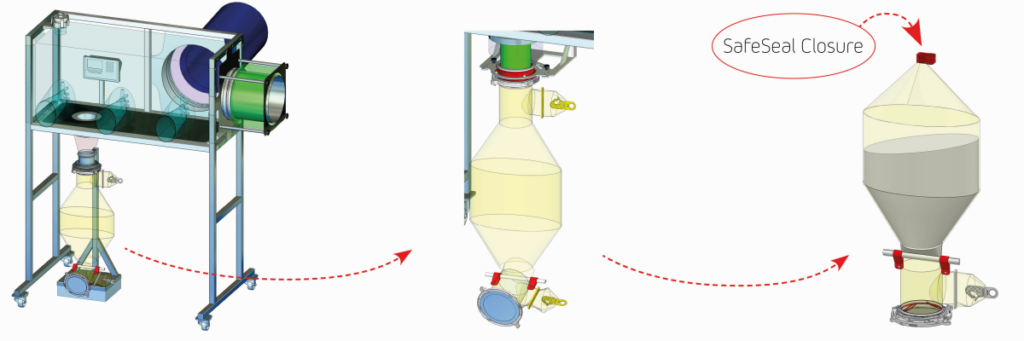

Tablets from the tablet press can be discharged/filled in a safe and contained way using a continuous liner in combination with the SafeSeal crimps. The bags could then be used as intermediate storage and introduced into a Flexible Isolator for the next step as charging of the coater.

The weighing and dispensing of the raw materials can be done in a SafeFlex isolator, from where the powder can be transferred in a closed way to the reactor with a Lugaia SafePort Bag.

The charging of the reactor can be done by using either SafeFlex isolator or SafePort bag depending on the process challenges.

The advantages of the SafeFlex isolator:

- High product and personal protection

- Easy handling

- Universal usability

- Foil with high tear resistance

- High quality

- Lower investment costs compared to rigid systems

- Elimination of cleaning and validation costs

- Integrable in existing systems

- Gamma or x-ray sterilization possible

- Containment can be done quickly and can be adjusted flexibly afterward

Examples of applications:

- Sampling

- Dosage/weighting

- Dispensing/Milling/Charging

- Reactor feed/charge

- Emptying the dryer

- Filter replacement

- Lyophilisation

- Handling of toxic API

Would you like to know more about this product scope or discuss your future projects? Please contact the Thurne specialist for any further information or for a quotation. We are always here to help you and find the best solution.

Magnus Karlström

Product Sales ManagerMAGNUS KARLSTRÖM

Product Sales Manager

B.Sc. Mechanical Engineering

PHONE NUMBER

Direct Phone: +46 8 5576 9333

Mobile: +46 709 326 731

Jari Valkama

Product Sales ManagerJARI VALKAMA

Product Sales Manager

M.Sc. Chemical Engineering

PHONE NUMBER

Mobile: +358 40 869 7736

Andris Putnins

Product Sales ManagerANDRIS PUTNINS

Product Sales Manager

B.Sc. Chemical Engineering, M.Sc. Materials Science

PHONE NUMBER

Direct Phone: +371 6616 3763

Mobile: +371 2689 6799

Adam Katia

Product Sales ManagerADAM KATIA

Product Sales Manager

B.Sc. Engineer

PHONE NUMBER

Mobile: +45 31 14 88 62